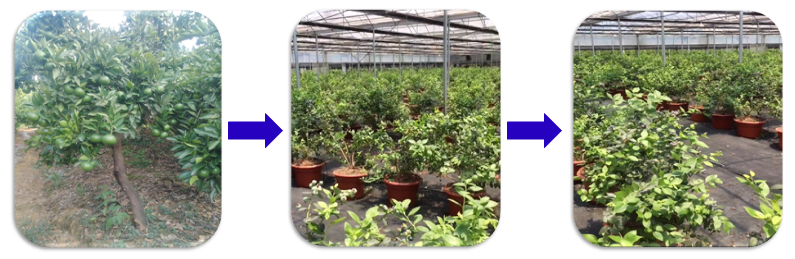

In agricultural production, the rainy season is a critical period for protecting flowers and fruit. If pesticide application proves ineffective, crop yields may be reduced by up to 30%. For orchards featuring tall trees with dense foliage, achieving uniform pesticide coverage on both the inner canopy and undersides of leaves has long posed a challenge for growers. Now, the ST - Air-Cooled High-Impact Atomising Nozzle offers an upgraded solution for mist spraying, helping to overcome this difficulty.

In greenhouses and orchards, the Ruby Impact Nozzle ensures pesticide droplets are evenly distributed across all plant surfaces, achieving 360-degree coverage without blind spots. High-pressure atomising nozzles play a vital role across cultivation, animal husbandry, fog generation, and cooling applications. The size of atomised particles is critical to the diffusion of chemicals, and precise control over particle size is key to determining efficacy, operational efficiency, and product quality.

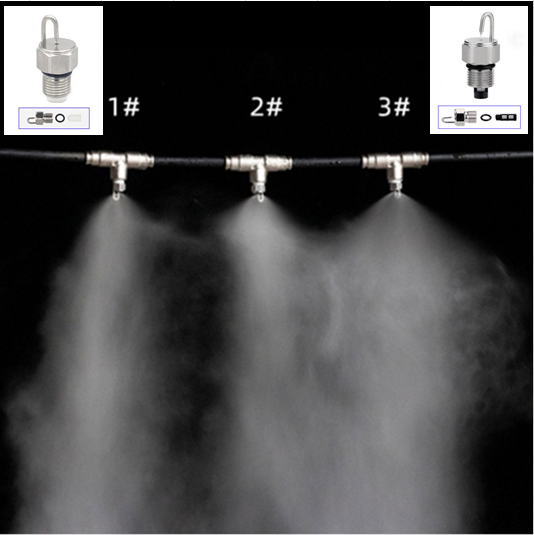

Why does the high-pressure impact atomising nozzle deliver such a remarkable effect? This nozzle features an integrated stainless steel construction with a filter mesh at its base, serving as the final filtration barrier before atomisation. A ruby disc is embedded at the nozzle's apex, its micro-orifices acting as the atomisation points. Water pressurised by the host unit is ejected through these orifices, striking the impact pin to disperse into a fine mist. The ruby impact nozzle produces atomised particles ranging from 5 to 15μm (micrometres). Should clogging occur, it can be cleaned. If the top impact pin is damaged, the nozzle becomes inoperable and requires replacement; thus, it must be handled with care during installation. This nozzle is available in multiple models, each offering distinct spray effects. Selecting the appropriate nozzle for the site is essential to achieve optimal results.

ST - Air-cooled high-pressure impact atomising nozzles deliver precise and efficient atomisation solutions:

The high-pressure atomising nozzle with needle is crafted from premium stainless steel. The standard nozzle features an orifice with a diameter of 0.006 inches (150 micrometres), capable of generating billions of ultrafine droplets per second. At an operating pressure of 2000 psi, the average droplet size is less than 10 microns – equivalent to one-tenth the diameter of a single human hair. The resulting mist evaporates rapidly, delivering remarkable results.

Key features include:

1. Internal component-free design for superior clog resistance;

2. Nozzle orifices ranging from 0.1mm to 0.5mm achieve exceptionally fine atomisation at pressures between 5kg and 30kg;

3. Power consumption of 3W per kilogram of mist output ensures minimal operating costs;

4. In certain applications, stainless steel perforated nozzles can replace many costly dual-fluid air atomising nozzles utilising compressed air or steam as the secondary fluid;

5. Non-perforated nozzles feature a 1/8" NPT tapered pipe fitting;

6. Features an integrated precision filter to prevent clogging, with the option to replace the base plastic filter element.

This nozzle, with its innovative design and outstanding performance, offers an efficient and economical solution for pesticide application in greenhouses and orchards, promising to elevate agricultural productivity to new heights.