In textile mills, any imbalance in humidity during production can lead to brittle fibre breakage and excessive static electricity. Dry yarn and thread breaks have long been persistent production challenges. Within high-dust workshops, the effectiveness of humidification for cotton spinning and yarn processing also impacts production efficiency. Among various humidification technologies, nozzle humidification has become the preferred choice across numerous sectors due to its cost-effectiveness and flexible application.

The performance of the atomising nozzle, specifically the particle size of the spray it produces, directly determines the final effectiveness of humidification.  When liquid flows at high velocity under water pressure ranging from 20kg to 70kg, it forms a centrifugal vortex within the guide vanes. This vortex expels minute hollow mist particles through the orifice, embodying the fundamental design principle of the atomising nozzle.

When liquid flows at high velocity under water pressure ranging from 20kg to 70kg, it forms a centrifugal vortex within the guide vanes. This vortex expels minute hollow mist particles through the orifice, embodying the fundamental design principle of the atomising nozzle.

The Three Major Challenges in Textile Humidification:

How Does the Atomising Nozzle Overcome Each One?

The essence of spray humidification lies in converting liquid into minute droplets and dispersing them into the surrounding environment to increase air humidity. Textile workshops exhibit an exceptionally high degree of sensitivity to humidity levels, yet many factories grapple with three major challenges: accelerated equipment corrosion where metal components swiftly develop rust in damp conditions; cumbersome installation and maintenance, with traditional interfaces proving both complex and time-consuming; and uneven atomisation, resulting in localised over-humidification or fibres becoming stiff and brittle.

This high-pressure atomising nozzle offers a bespoke solution.

• Durable and corrosion-resistant material: Constructed from nickel-plated brass incorporating nickel-chromium elements, it exhibits exceptional corrosion resistance and oxidation resistance. It remains rust-free even during prolonged use in the humid environments of textile workshops.

• Effortless installation and maintenance: Featuring a threaded connection design, replacement and installation are straightforward. Textile factories can swiftly upgrade equipment without concerns over downtime for maintenance.

• Precise and Uniform Atomisation: Utilising CNC machining and mirror-finishing techniques, the liquid forms a centrifugal vortex under 20kg to 70kg water pressure. This produces fine, uniform hollow mist droplets, achieving precisely regulated humidity levels in textile workshops. Consequently, fibre resilience and weaving efficiency are simultaneously enhanced.

What gives it such appeal in fields beyond textiles?

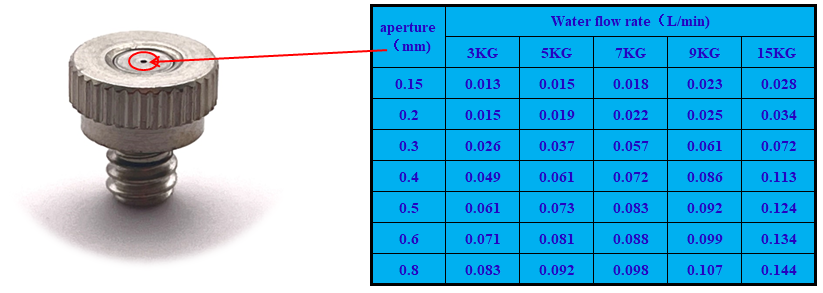

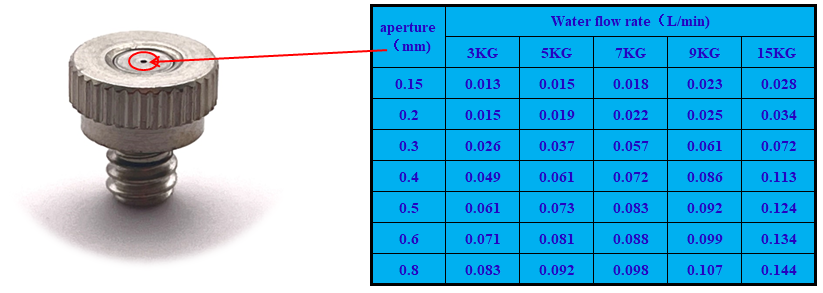

(Nozzle Orifice Selection (Product Performance Parameters):

The capabilities of atomising nozzles extend far beyond textiles:

• Horticulture sector: Fine atomised particles create misty landscapes for garden design.

• Environmental protection: Uniform misting effectively suppresses dust in dust suppression and humidity control applications while regulating microclimate humidity. Ideal for dust suppression and cooling on construction sites and in industrial facilities.

• Livestock farming and disinfection: The uniform atomisation ensures thorough dispersion of disinfectants and deodorants, effortlessly handling odour control and disinfection in breeding facilities, as well as cooling in livestock operations.

All this stems from its core principle—efficiently breaking liquids into minute droplets to precisely meet diverse application requirements through atomisation.

Beyond humidification, what other benefits does it offer textile mills?

For textile factories, selecting the right humidification equipment transcends mere environmental improvement:

• Cost reduction and efficiency gains: Corrosion-resistant and long-lasting, reducing equipment replacement costs; swift installation and maintenance without disrupting production schedules.

• Quality enhancement: Uniform humidity maintains fibre resilience, boosting yield rates and ensuring consistent fabric texture.

From the humidity guardian of textile workshops to a versatile solution for landscaping, environmental dust suppression, animal husbandry, and disinfection, the ST high-pressure atomising nozzle demonstrates its prowess: a premium humidification solution that addresses industry pain points while excelling across diverse applications.

When liquid flows at high velocity under water pressure ranging from 20kg to 70kg, it forms a centrifugal vortex within the guide vanes. This vortex expels minute hollow mist particles through the orifice, embodying the fundamental design principle of the atomising nozzle.

When liquid flows at high velocity under water pressure ranging from 20kg to 70kg, it forms a centrifugal vortex within the guide vanes. This vortex expels minute hollow mist particles through the orifice, embodying the fundamental design principle of the atomising nozzle.