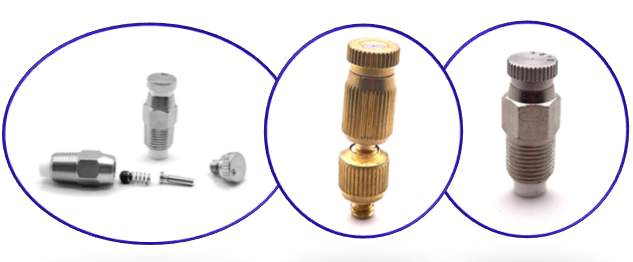

Product Advantages and Features:

- Copper construction with nickel and chromium elements provides corrosion resistance, strong oxidation resistance, and minimal rusting

- Simple connection, easy replacement and installation, extended service life

- Copper construction withstands both high and low temperatures.

- CNC machining with integral mirror-finishing optimises performance in spray applications.

- Uniform atomisation and efficient heating deliver superior performance across diverse sectors.

- Integrated anti-clogging filter plug and anti-drip rubber seal.

Nozzle Design Principle: Liquid flows at high velocity under water pressure ranging from 20kg to 70kg, forming a centrifugal vortex within the guide vanes. This produces fine hollow-core mist droplets ejected through the nozzle orifice.

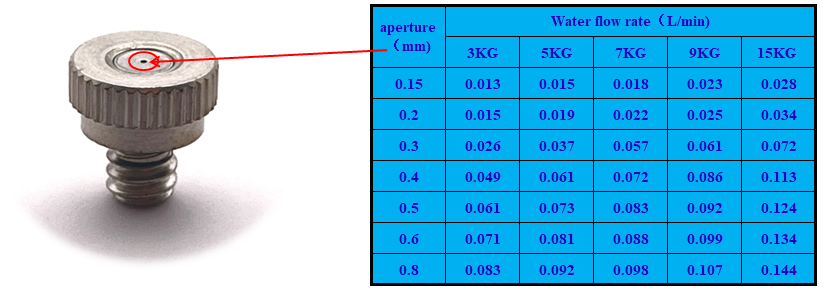

Nozzle Orifice Selection (Product Performance Parameters):

Note: 1. Greater pressure yields superior atomisation. To prevent nozzle fittings from detaching, operate within a pressure range of 3kg to 15kg, preferably between 7kg and 9kg. (Pressure must not exceed 15kg).

2. For mains water pressure, use nozzles with an orifice diameter of 0.3mm or larger.

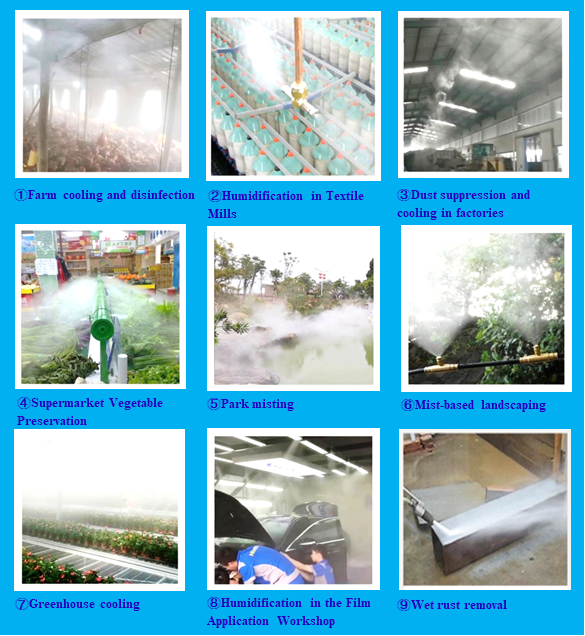

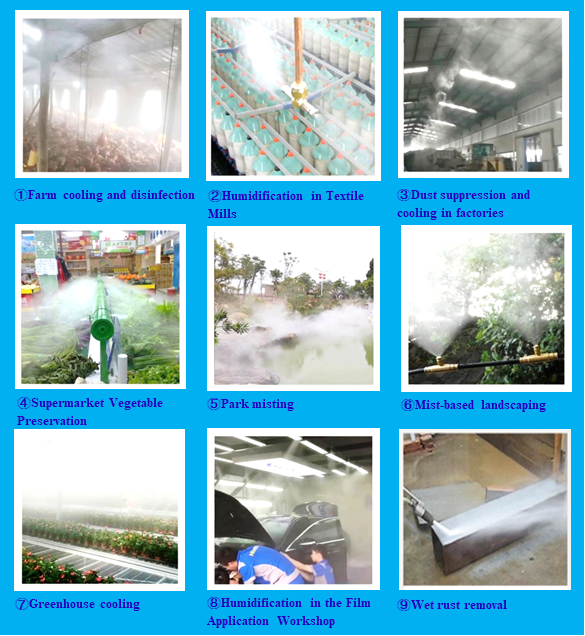

Applications: Factory cooling, humidification with fine mist dust suppression, seedling cultivation, landscaping and outdoor use, cooling systems, aquaculture, disinfection spray nozzles