In the textile mill, humidity imbalances have always been a persistent headache. The slightest oversight during production can lead to brittle fibre breakage and excessive static electricity. Particularly with dry yarn, thread breakage is a frequent concern. Indeed, humidity issues often present the challenge of ‘yarn breakage’ during production, especially in high-dust workshops where humidification effectiveness directly impacts productivity.

I have personally tested several humidification techniques in the laboratory and found that nozzle humidification is indeed the most effective option. Not only is nozzle humidification cost-effective, but it also offers considerable flexibility in application, which has convinced me that it stands as one of the optimal choices for the textile industry.

The performance of spray nozzles, particularly the particle size of the spray droplets, is pivotal to the humidification effect. I have tested this under varying pressures and observed that when liquid flows at water pressures ranging from 20kg to 70kg, it forms centrifugal vortices. These generate minute mist droplets, delivering exceptionally uniform humidification. Such fine hollow mist droplets, though seemingly simple, prove highly effective in practical applications for regulating workshop humidity and mitigating static electricity issues.

The Three Major Challenges in Textile Humidification:

How Do Spray Nozzles Overcome These Challenges?

When I began utilising spray humidification, I realised the essence of humidification lies in converting liquid into minute droplets that disperse uniformly into the air, thereby increasing air humidity. However, within our workshop, humidity sensitivity is exceptionally high. After a period of testing, I identified several issues:

Firstly, equipment corrosion accelerates, particularly with metal components rusting rapidly in humid environments. One of my older units was rendered unusable due to rust. Secondly, traditional humidification equipment proves cumbersome to install and maintain; when replacing units, I spent considerable time managing interfaces, wasting significant effort and resources. Thirdly, spray distribution occasionally proved uneven, leading to excessive moisture in certain areas and compromising fibre quality.

In practice, I encountered issues with uneven humidity distribution and equipment corrosion, alongside the complex installation and susceptibility to rust of conventional systems. After trialling several humidification devices—including air-blow nozzles, mixed-flow nozzles, fan-shaped nozzles, and conical nozzles—none achieved the desired spray consistency. Ultimately, I switched to testing high-pressure spray nozzles. Surprisingly, the high-pressure spray nozzles achieved precise humidity control through straightforward installation and uniform misting, while the corrosion-resistant materials significantly extended the equipment's operational lifespan.

High-pressure spray nozzles provide bespoke solutions:

• Durable and corrosion-resistant material: Having personally installed this nozzle, I can attest that its nickel-plated brass construction, incorporating nickel-chromium elements, demonstrates exceptional corrosion resistance. Even after prolonged use in humid conditions, the nozzle remains rust-free, which is highly reassuring.

• Simple installation and maintenance: Upon first fitting, I noted its straightforward threaded design, allowing installation within minutes. Compared to previous complex connectors, this design saves considerable time and effort, significantly boosting efficiency.

• Precise and Uniform Spraying: Through CNC machining and mirror polishing techniques, this nozzle generates exceptionally fine and uniform hollow mist droplets under water pressures ranging from 20kg to 70kg. Several practical tests confirmed more precise humidity control, eliminating localised over-humidification. My workshop now maintains optimal humidity levels, resulting in markedly improved fibre resilience and weaving efficiency.

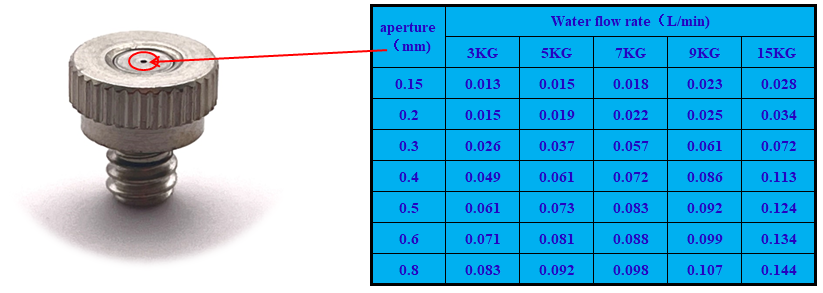

(Nozzle Orifice Selection (Product Performance Parameters):

What other attractions does it hold beyond the textile industry?

It was only when I witnessed this nozzle's performance beyond the textile industry that I realised its potential extended far beyond that:

Horticulture: I have experimented with nozzles to create mist effects in garden designs. The fine spray particles lend gardens a misty, ethereal beauty, fostering an exceptionally natural ambience throughout the environment.

• Environmental Protection: In a project I participated in, this misting technology proved highly successful when applied to construction sites and industrial facilities. The uniform atomisation effectively suppresses dust, reducing airborne particulates and significantly improving environmental conditions.

• Livestock Management and Disinfection: I have observed this spray being utilised in livestock facilities for disinfection and odour control. The nozzle's uniform mist ensures thorough dispersion of disinfectants, yielding remarkable results. Most impressively, it also provides excellent cooling effects within the livestock environment.

Through these applications, I have become increasingly aware of the core principle behind spray nozzles: by atomising liquids into fine droplets, they precisely meet diverse requirements.

What other benefits can spray nozzles offer textile mills besides humidification?

For my daily work at the textile mill, selecting suitable humidification equipment serves more than just improving workshop conditions:

• Cost reduction and efficiency gains: I've found the nozzles to be not only durable but also corrosion-resistant, significantly reducing equipment replacement costs. Installation and maintenance are swift, minimising disruption to the production process – which greatly aids in maintaining productivity.

• Enhancing quality: Since adopting these nozzles, workshop humidity has stabilised, preserving fibre resilience. Fabric quality has become consistent, and production efficiency has seen a marked improvement.

From humidity control in textile workshops to multifunctional solutions for horticulture, environmental dust suppression, livestock farming and disinfection, the ST high-pressure spray nozzle demonstrates its versatility: not only does it address the pain points within my industry, but it also excels across multiple sectors.